Brass Turned Components

Brass Turned Components Specification

- Material

- BRASS

- Finish

- Natural

- Surface Finishing

- NATURAL

- Tolerance

- 0.05 Millimeter (mm)

- Product Type

- Brass Turned Components

- Type

- Brass Turned Components

- Surface Materials

- Brass

- Surface Treatment

- Natural

- CNC Machining

- Yes

- Dimension (L*W*H)

- Customized as per drawing

- Weight

- As per specification

- Color

- Natural

- Corrosion Resistance

- Yes

- Application

- Electrical, Electronic, Automotive, and Mechanical Industries

- Customization

- Available as per customer specification

- Thread Type

- Metric/Imperial as per customer requirements

- Hardness

- 60-80 HRB (as per Brass Grade)

- Standard

- IS, BS, DIN or as per requirement

- Technique

- CNC Turning and Precision Machining

- Minimum Order Quantity

- As per agreement

- Packaging

- Export Quality Packing

Brass Turned Components Trade Information

- Minimum Order Quantity

- 1000 Pieces

- FOB Port

- Ahmedabad

- Supply Ability

- 200000 Pieces Per Month

- Delivery Time

- 30 Days

- Packaging Details

- In Box

- Main Domestic Market

- All India

About Brass Turned Components

As a Leading Manufacturer for Brass Turned Parts, we have made a name in High Volume and Mass Production of Precision Brass Turned Parts. We manufacture and export wide variety of Turned Parts including Brass Turned Parts. We are serving manufactured range of Turned Parts in Automotive, Automobile, Mechanical, Electrical, Electronics, Medical, Plastic Injection Molding and many other industries as well. All Turned Parts are manufactured with Highest Industrial Grades and Standard Norms. Brass Turned Parts are available with High Accuracy and Precision. The range of turned parts are widely use for various machining and turning procedures & highly application in high heat dissipation area.

Features:

Corrosion Resistant

Brass Turned Parts are available in Simple to Complex Tolerance.

High Machining Properties.

Extruded as well Casted Turned Parts.

Dimensionally Accurate and Precise

High Shrinkage Properties.

RoHS Compliant.

Customization Available.

Precision Machining for Reliable Performance

Utilizing CNC turning and advanced machining techniques, our brass turned components offer tight tolerances of 0.05 mm, ensuring maximum precision and durability. Each piece is rigorously produced according to industry standards such as IS, BS, and DIN or tailored to specific drawing requirements. Our expertly crafted components are suitable for even the most demanding industrial applications.

Extensive Customization and Application Flexibility

Our brass components are available with both metric and imperial thread types, and their dimensions and surface finish can be fully customized. Whether used in electrical assemblies, electronic devices, automotive engines, or mechanical systems, these components ensure compatibility and optimal performance across a broad spectrum of industries.

Quality Assurance and Export-Grade Packaging

All components undergo strict quality controls to ensure consistent hardness (60-80 HRB) and superior corrosion resistance. Export-quality packaging protects products during transit, upholding integrity for global distribution. Manufacturers, suppliers, and service providers in India ensure timely delivery and reliable after-sales support.

FAQ's of Brass Turned Components:

Q: How are brass turned components manufactured to meet precise customer specifications?

A: Brass turned components are produced using CNC turning and precision machining, allowing for high accuracy (tolerance of 0.05 mm) and customization based on customer drawings or specifications. We adhere to IS, BS, DIN, or client-defined standards to ensure the final product matches specific application needs.Q: What industries typically benefit from using brass turned components?

A: These components are widely employed in the electrical, electronic, automotive, and mechanical industries due to their excellent conductivity, corrosion resistance, and mechanical strength. Their versatile attributes make them ideal for varied industrial applications.Q: When should metric or imperial thread types be selected for a project?

A: The choice between metric and imperial thread types depends on where and how the components will be integrated. Metric threads are standard in many international applications, while imperial threads are often preferred in regions or systems that follow British or American standards. We provide both types to cater to any project requirements.Q: Where can these brass components be sourced and who are the available suppliers?

A: We are established as a distributor, exporter, manufacturer, supplier, service provider, and trader in India, enabling us to supply globally with export-quality packaging. Customers can reach out for customized orders and reliable delivery support.Q: What are the benefits of using CNC-machined brass components over traditional fabricated parts?

A: CNC-machined brass components provide superior precision, consistent quality, and better tolerance control. The process ensures parts are durable and fit for critical applications, reducing assembly errors and enhancing overall product reliability.Q: How does the corrosion resistance of your brass components improve product longevity?

A: Our brass components offer high corrosion resistance due to material selection and a natural finish, minimizing degradation over time. This helps extend the lifespan of products in harsh environments and reduces the need for frequent replacements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Brass Inserts Category

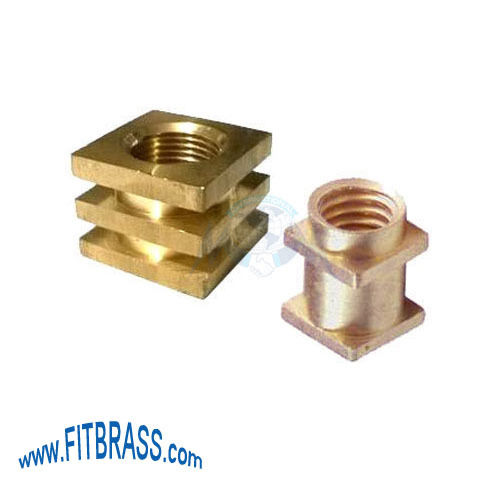

Brass Square Insert

Minimum Order Quantity : 10000 Pieces, ,

Material : Brass

Finish : Natural

Usage : Moulding

Product Type : Brass Square Insert

Surface Finishing : As required

Brass Bi-Sert Insert

Minimum Order Quantity : 10000 Pieces, ,

Material : Brass

Finish : Natural

Usage : Molding

Product Type : Brass BiSert Insert

Surface Finishing : Machined

Brass Barbed Expansion Insert

Minimum Order Quantity : 10000 Pieces, ,

Material : Brass

Finish : Natural

Usage : molding

Product Type : Brass Barbed Expansion Insert

Surface Finishing : As required

Brass Multi Headed Insert

Minimum Order Quantity : 10000 Pieces, ,

Material : Brass

Finish : Natural

Usage : Molding

Product Type : Brass Multi Headed Insert

Surface Finishing : As required

|

M M INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry